1. General introduction:

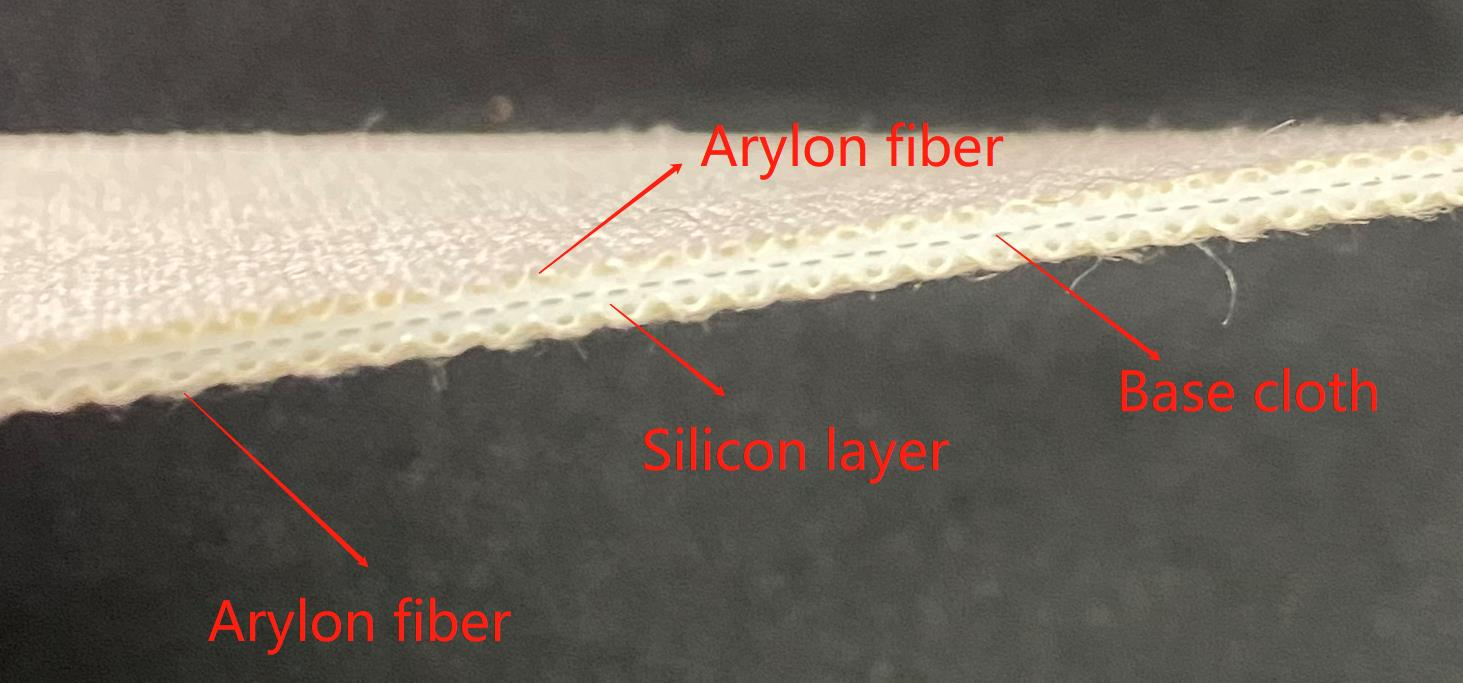

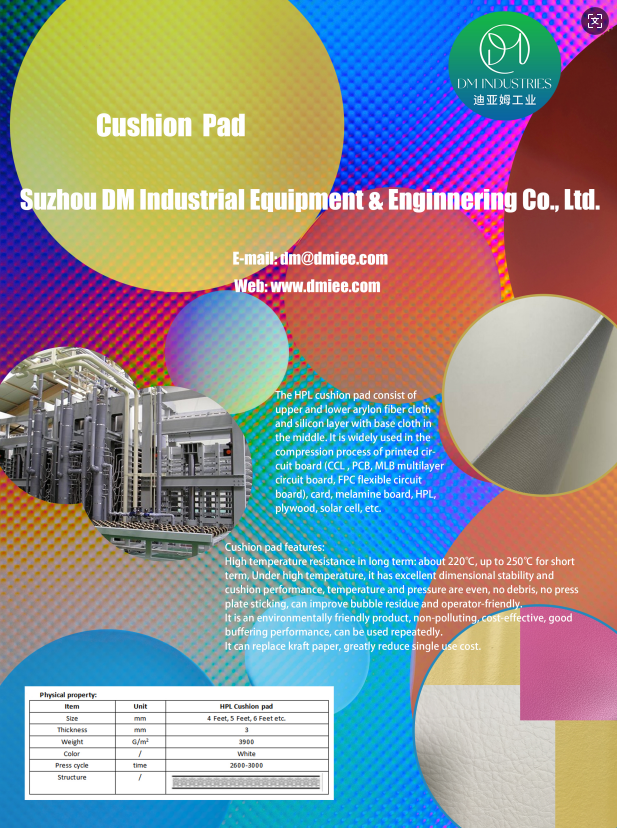

The HPL cushion pad consist of upper and lower arylon fiber cloth and silicon layer with base cloth in the middle. It is widely used in the compression process of printed circuit board (CCL , PCB, MLB multilayer circuit board, FPC flexible circuit board), card, melamine board, HPL, plywood, solar cell, etc.

2. Cushion pad features:

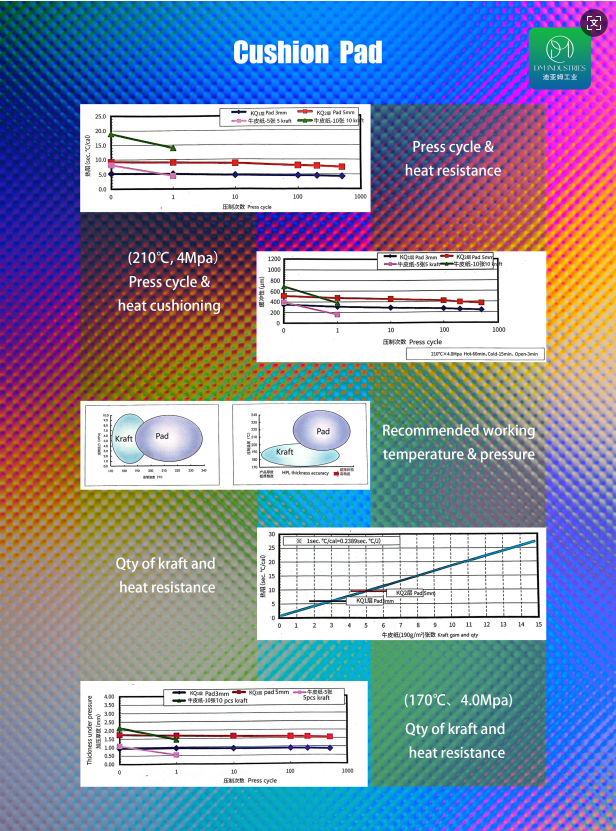

High temperature resistance in long term: about 220℃, up to 250℃ for short term,

Under high temperature, it has excellent dimensional stability and cushion performance, temperature and pressure are even, no debris, no press plate sticking, and improve bubble residue.

It is an environmentally friendly product, non-polluting, cost-effective, good buffering performance, can be used repeatedly.

It can replace kraft paper, greatly reduce single use cost.

3. Physical property:

Item | Unit | HPL Cushion pad |

Thickness | mm | 1.6mm |

Color | / | White |

Service life | Press cycle | Working temp. 130 ℃, unit pressure 57kg/cm2: about 500 |

Grammage | g/m2 | 1550 |

Thermal conductivity | W/mK | 0.056 |

Structure | / | |